Shot peening is the mechanical operation of introducing residual compressive surface stress on mechanical parts which are subjected to dynamic conditions like Turbine blades, springs etc. The compressive stress so produced increases fatigue life and stress corrosion resistance properties of shot peened parts. The process of Shot peening is accomplished by propelling spherical shots on such parts with controlled parameters.

The selection of various parameters like shot dimensions, shape, physical properties, shot speed, angle of projection and exposure time depends upon requirement of shot peening intensity and coverage. The shot peening is first carried out on test samples called Almen Strip on pre-selected parameters. Based on results of shot peened Almen Strips, the parameters are established and the actual component is shot peened under the same established parameters.

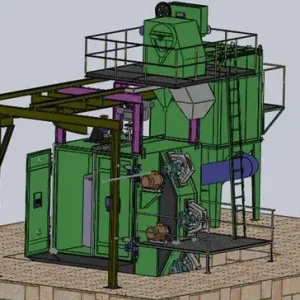

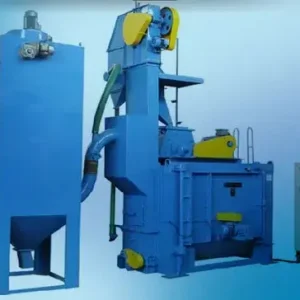

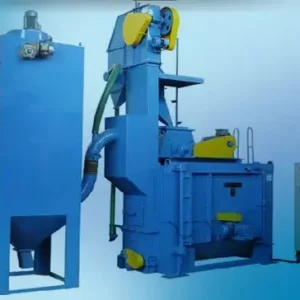

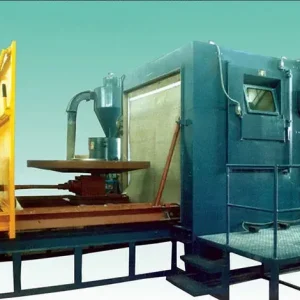

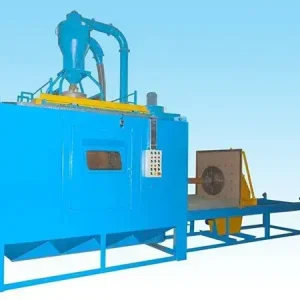

For shot peening applications, air operated dry type shot peening machines along with shot classifier and shot separator system are quiet popular in use. AEROWHEEL has designed , manufactured and supplied custom built semi-automatic shot peening machines to various customers for their intended purpose. The subject machines are featured with automatic shot recovery , dust collection and optional shot classifier with shot separator.

For Further information please write to undersign.

Best Regards,

Innovative Features in Modern Shot Blasting Machines: An Overview by Indian Manufacturers

Blasting Rooms at AeroWheel Surface Finishing: Precision and Quality in Every Detail

SHOT PEENING PROCESS AND MACHINES

Vivek Mehra