Customization Options Available from Shot Blasting Machine Manufacturers

Shot blasting machines play a vital role in surface preparation and finishing across various industries. To meet diverse application requirements, manufacturers offer numerous customization options, allowing customers to tailor machines to their specific needs. Customization enhances efficiency, improves performance, and ensures the machine fits seamlessly into your production process. Here’s a detailed guide to the customization options available from leading shot blasting machine manufacturers.

1. Abrasive Media Handling

Description: Customization in abrasive media handling allows the machine to accommodate different types of media for various applications.

- Media Types: Options to use steel shot, grit, glass beads, aluminum oxide, plastic media, or custom blends.

- Media Flow Control: Adjustable flow control systems to regulate the media flow rate for precise blasting.

Benefits:

- Ensures compatibility with specific surface treatment requirements.

- Enhances the effectiveness of the blasting process.

- Reduces wear on machine components by using suitable media.

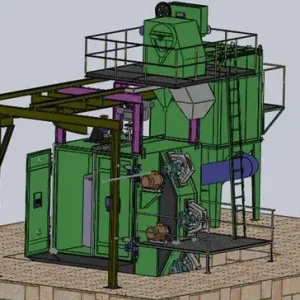

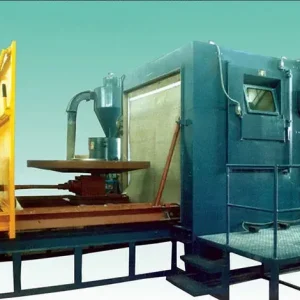

2. Blasting Chamber Size and Configuration

Description: Customizing the size and configuration of the blasting chamber to match the dimensions and shapes of the parts you need to process.

- Chamber Dimensions: Customizable chamber sizes to accommodate larger or uniquely shaped parts.

- Multiple Chambers: Option for multiple chambers to allow simultaneous processing of different parts.

Benefits:

- Increases processing efficiency for various part sizes.

- Reduces the need for multiple passes, saving time and resources.

- Enhances flexibility in handling diverse production requirements.

3. Automation and Control Systems

Description: Advanced automation and control systems can be customized to optimize the blasting process.

- Programmable Logic Controllers (PLCs): Customized PLCs for automated control of blasting parameters.

- Human-Machine Interface (HMI): User-friendly interfaces for easy monitoring and adjustments.

- Remote Monitoring: Integration of remote monitoring systems for real-time data and control.

Benefits:

- Enhances precision and consistency in the blasting process.

- Reduces labor costs with automated operations.

- Provides real-time insights for improved process control.

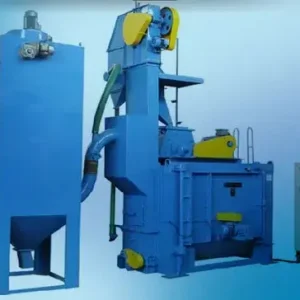

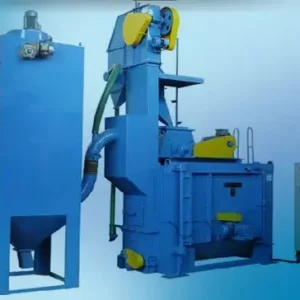

4. Loading and Unloading Mechanisms

Description: Custom loading and unloading mechanisms improve workflow and efficiency.

- Conveyor Systems: Customizable conveyor systems for continuous processing of parts.

- Robotic Arms: Integration of robotic arms for automated loading and unloading.

- Turntables and Trolleys: Custom turntables and trolleys for easy handling of heavy or awkwardly shaped parts.

Benefits:

- Streamlines the workflow, reducing manual handling.

- Increases processing speed and throughput.

- Enhances safety by minimizing manual intervention.

5. Dust Collection and Filtration Systems

Description: Custom dust collection and filtration systems ensure a clean and safe working environment.

- High-Efficiency Filters: Customizable filters to handle specific dust and particle types.

- Dust Extraction Units: Integration of dust extraction units for effective removal of airborne particles.

- Noise Reduction Features: Custom noise reduction features to minimize operational noise.

Benefits:

A Comprehensive Guide to Tumblast Shot Blasting Machines

How to Troubleshoot Common Issues with Shot Blasting Machines

Understanding Shot Blasting Machines: A Comprehensive Guide

- Maintains air quality and ensures compliance with environmental regulations.

- Protects worker health and safety.

- Reduces maintenance costs by preventing dust build-up in the machine.

6. Wear Parts and Linings

Description: Custom wear parts and linings enhance the durability and longevity of the machine.

- Replaceable Liners: Customizable liners made from wear-resistant materials.

- Specialized Nozzles and Blast Wheels: Options for specialized nozzles and blast wheels to handle specific media and applications.

Benefits:

- Extends the lifespan of the machine by reducing wear.

- Optimizes performance with parts designed for specific applications.

- Reduces downtime with easily replaceable components.

7. Energy Efficiency Enhancements

Description: Custom options to improve the energy efficiency of shot blasting machines.

- Variable Speed Drives: Integration of variable speed drives for energy-efficient motor control.

- Energy Recovery Systems: Custom energy recovery systems to reclaim and reuse energy.

- Efficient Blasting Media Reclaim Systems: Systems to reclaim and recycle blasting media efficiently.

Benefits:

- Reduces operational costs by lowering energy consumption.

- Supports sustainability initiatives with energy-efficient technology.

- Improves overall machine performance and cost-effectiveness.

8. Specialized Applications and Industry-Specific Solutions

Description: Custom solutions for specialized applications and industry-specific requirements.

- Surface Preparation for Coating: Custom configurations for surface preparation prior to coating or painting.

- Deburring and Deflashing: Specialized machines for deburring and deflashing applications.

- Peening: Custom shot peening solutions for enhancing the fatigue strength of metal components.

Benefits:

- Ensures the machine meets the unique demands of specific applications.

- Enhances the quality and precision of surface treatment.

- Provides industry-specific solutions for optimal performance.

Conclusion

Customization options from shot blasting machine manufacturers like AeroWheel Surface Finishing, Wheelabrator, Rosler, Goff Inc., and Sinto America allow businesses to tailor machines to their specific needs, ensuring optimal performance and efficiency. By customizing abrasive media handling, blasting chamber size, automation and control systems, loading and unloading mechanisms, dust collection systems, wear parts, energy efficiency, and specialized applications, you can significantly enhance the effectiveness of your shot blasting operations. Investing in customized solutions ensures that your machine is perfectly suited to your production requirements, providing long-term value and superior results.