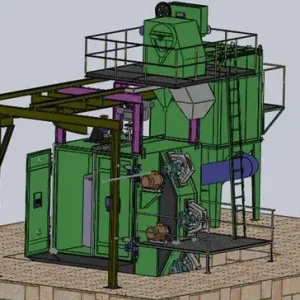

Automated shot blasting systems have revolutionized the surface preparation process by enhancing efficiency, productivity, and consistency. Indian manufacturers have been at the forefront of developing advanced automated shot blasting systems that cater to the diverse needs of industries. In this article, we will explore how Indian manufacturers are leveraging automation technology to enhance efficiency in shot blasting processes.

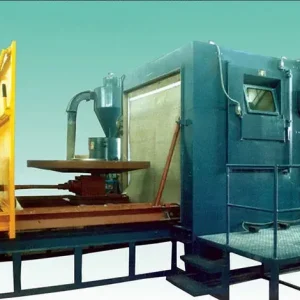

- Robotic Loading and Unloading: Indian manufacturers are integrating robotics into shot blasting systems to automate the loading and unloading of workpieces. Robotic arms equipped with specialized grippers can efficiently handle and position the workpieces, eliminating the need for manual intervention. This not only improves the overall throughput but also ensures precise and consistent placement of workpieces for optimal blasting results.

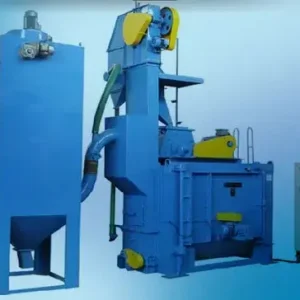

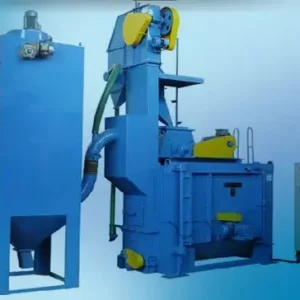

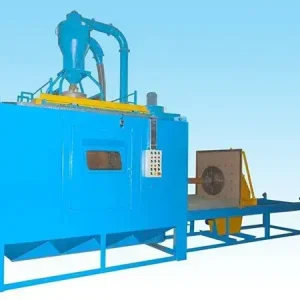

- Conveyor Systems: To streamline the shot blasting process, Indian manufacturers incorporate automated conveyor systems into their machines. These systems are designed to transport workpieces from the loading area to the blasting chamber and then to the unloading section. By eliminating manual handling and reducing downtime between blasting cycles, conveyor systems significantly enhance the overall efficiency and productivity of the shot blasting process.

- Programmable Control Systems: Indian manufacturers utilize programmable control systems to automate and optimize the shot blasting parameters. These systems enable operators to set and adjust blasting parameters such as blast intensity, duration, and movement patterns. By precisely controlling these parameters, manufacturers can achieve consistent and uniform results across all workpieces, ensuring high-quality surface preparation.

- Sensor-Based Process Control: Indian manufacturers integrate sensors and advanced control algorithms into their automated shot blasting systems. These sensors monitor and measure various parameters such as blast pressure, media flow rate, and workpiece positioning. The data collected by these sensors is used to continuously optimize the blasting process, ensuring efficient media usage, minimizing waste, and maximizing productivity.

- Remote Monitoring and Control: Indian manufacturers incorporate remote monitoring and control capabilities into their automated shot blasting systems. Operators can remotely access and monitor the machine’s performance, adjust parameters, and receive real-time notifications about the process. This enables manufacturers to remotely manage multiple shot blasting systems, optimize production schedules, and address any issues promptly, leading to improved operational efficiency.

- Integration with IoT and Data Analytics: Indian manufacturers are leveraging the power of the Internet of Things (IoT) and data analytics to enhance the efficiency of shot blasting systems. By connecting machines to a network and collecting data, manufacturers can gain valuable insights into machine performance, maintenance needs, and process optimization. These insights enable proactive decision-making, predictive maintenance, and continuous improvement of the shot blasting process.

- Energy Efficiency and Sustainability: Indian manufacturers prioritize energy efficiency and sustainability in their automated shot blasting systems. They incorporate energy-saving features such as variable frequency drives, optimized blast wheel designs, and efficient dust collection systems. These features not only reduce energy consumption but also contribute to a cleaner and healthier working environment.

The advancements in automated shot blasting systems by Indian manufacturers have significantly enhanced efficiency, productivity, and overall process control. By integrating robotics, conveyor systems, programmable control systems, sensors, remote monitoring, and IoT capabilities, these manufacturers are providing cutting-edge solutions that cater to the evolving needs of industries. The result is improved throughput, higher quality surface preparation, and reduced operational costs for businesses using automated shot blasting systems.

Shot blasting machine manufacturers in India

In conclusion, Indian manufacturers are leading the way in enhancing shot blasting efficiency through automated systems. The incorporation of robotics, conveyor systems, programmable control, sensors, remote monitoring, and IoT integration has revolutionized the shot blasting process. These advancements have not only improved productivity and consistency but also enhanced energy efficiency and sustainability. With their focus on automation and technological innovation, Indian manufacturers continue to provide efficient and cost-effective solutions to industries worldwide.

Conquering the Grit: Why AeroWheel Surface Finishing Reigns Supreme in India's Shot Blasting Arena