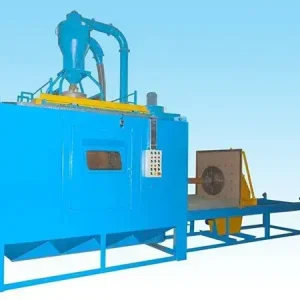

Shot blasting machines have found extensive applications in the steel industry, and Indian manufacturers have demonstrated their expertise in providing innovative solutions to meet the industry’s unique requirements. In this article, we will explore the diverse applications of shot blasting machines in the steel industry and delve into the expertise of Indian manufacturers in delivering tailored solutions.

- Surface Preparation for Coating: Shot blasting machines are extensively used in the steel industry to prepare surfaces for coating applications. Prior to the application of protective coatings such as paint or powder, it is crucial to remove rust, scale, and other contaminants from the steel surface. Indian manufacturers offer shot blasting machines with varying capacities and configurations to effectively clean and prepare steel surfaces, ensuring optimal adhesion of coatings and prolonging their lifespan.

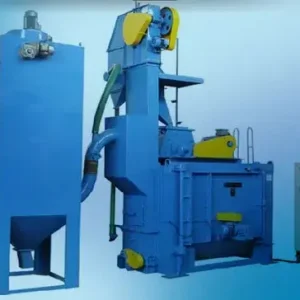

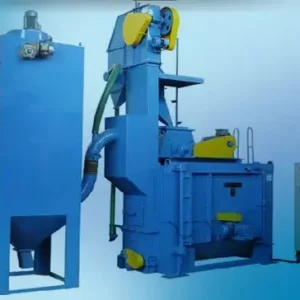

- Descaling of Steel Products: Shot blasting machines play a vital role in the descaling process of steel products. During manufacturing or post-processing, steel surfaces often develop scales or oxides that need to be removed. Indian manufacturers provide shot blasting machines with specialized features such as adjustable blast parameters and specific abrasive media to efficiently remove scales and achieve a clean and uniform surface finish.

- Cleaning and Deburring of Steel Components: Shot blasting machines are utilized for the thorough cleaning and deburring of steel components. Indian manufacturers offer a range of shot blasting equipment designed to remove dirt, grease, oil, burrs, and other impurities from steel parts. The machines deliver consistent and high-velocity abrasive impact, effectively cleaning the components and ensuring their readiness for subsequent manufacturing processes or assembly.

- Surface Texturing and Profiling: Shot blasting machines are employed in the steel industry to create specific surface textures and profiles. Indian manufacturers understand the importance of surface finish in steel applications and provide shot blasting solutions that can impart desired textures, such as matte, etched, or roughened surfaces. This enhances the aesthetic appeal, improves paint adhesion, and provides functional benefits like enhanced grip or reduced glare in various steel products.

- Shot Peening for Strength Enhancement: Shot peening is a critical process in the steel industry aimed at enhancing the strength and durability of components. Indian manufacturers offer shot blasting machines with specialized capabilities for shot peening, which involves bombarding steel surfaces with small steel shots to induce compressive stress and improve fatigue resistance. These machines are designed to deliver precise shot peening parameters, ensuring optimal results in terms of component strength and performance.

- Rust and Corrosion Removal: Shot blasting machines are employed in the steel industry for the removal of rust and corrosion from steel surfaces. Indian manufacturers provide robust and efficient shot blasting equipment that can effectively eliminate rust layers and corrosion spots, restoring the steel’s integrity and preventing further deterioration. This process significantly contributes to maintaining the quality and longevity of steel components.

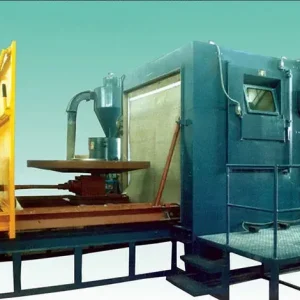

- Surface Cleaning and Reconditioning of Steel Structures: Shot blasting machines are extensively used for cleaning and reconditioning steel structures such as bridges, pipelines, storage tanks, and industrial equipment. Indian manufacturers offer powerful shot blasting systems capable of handling large-scale structures, removing years of grime, coatings, and corrosion. These machines ensure thorough cleaning, restoring the structural integrity and extending the service life of steel infrastructure.

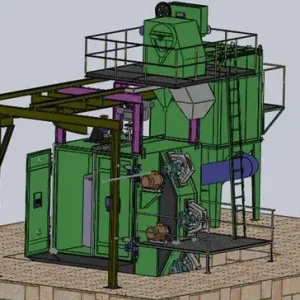

Shot blasting machine manufacturers in India

Indian manufacturers have established themselves as leaders in providing shot blasting machines that cater to the diverse applications within the steel industry. Their expertise lies in offering customized solutions tailored to specific needs, ensuring efficient surface preparation, cleaning, descaling, and strengthening of steel components. With a focus on technological advancements, quality assurance, and adherence to industry standards, Indian manufacturers continue to support the steel industry with reliable and high-performance shot blasting equipment.

Advantages of Airless Shot Blasting Machines over Traditional Blasting Methods

The Role of Shot Blasting Machines in Surface Preparation: A Comprehensive Guide