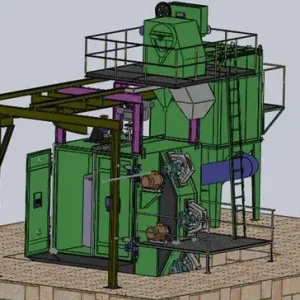

As one of the premier Airless Tumblast Type Shot Blasting Machine Manufacturers in Bengaluru, AeroWheel Surface Finishing provides advanced solutions for surface cleaning, descaling, rust removal, and deburring of metal components. Our machines are designed for batch cleaning of small and medium-sized parts, making them ideal for high-volume industrial applications.

What is an Airless Tumblast Type Shot Blasting Machine?

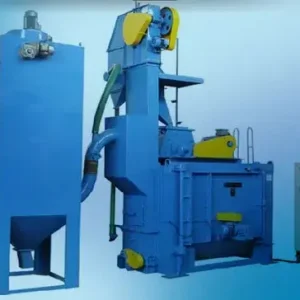

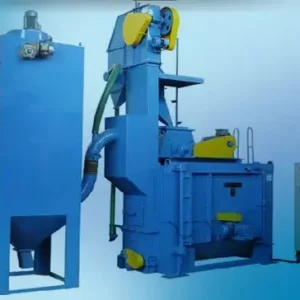

An Airless Tumblast Shot Blasting Machine is designed for cleaning and surface preparation of smaller parts in bulk. The components are loaded into a rotating drum, where they are tumbled and exposed to high-velocity abrasive media propelled by blasting wheels. This ensures thorough cleaning from all angles, making the machine suitable for industries requiring precision cleaning of large quantities of parts.

Key Features of AeroWheel’s Airless Tumblast Type Shot Blasting Machines:

- High Production Efficiency: Our tumblast machines are designed to clean multiple components simultaneously, reducing cycle times and improving production efficiency.

- Durable Construction: Manufactured using high-quality materials, these machines are built to handle the rigors of continuous industrial use, offering a long service life.

- Uniform Cleaning: The tumbling action ensures that each component is exposed to the blast stream from multiple angles, resulting in even surface treatment.

- Low Maintenance: Designed for easy maintenance, our machines have a user-friendly interface that minimizes downtime and operational costs.

- Customizable Options: We offer a range of models and configurations tailored to meet the specific requirements of your application, including capacity, abrasive media, and automation.

Applications of Airless Tumblast Type Shot Blasting Machines:

- Automotive Industry: Ideal for cleaning engine parts, suspension components, and metal castings, ensuring that the surfaces are free from rust, scale, and dirt.

- Metal Fabrication: Perfect for cleaning small metal parts used in fabrication processes, ensuring they are ready for coating, plating, or further processing.

- Foundries: Widely used in foundries to clean castings, remove sand, and eliminate surface contaminants, improving the quality and finish of the final product.

- Forging Industry: Efficiently cleans and prepares forged components, removing scale, oxides, and surface contaminants for better surface finishing.

- Hardware Manufacturing: Used for bulk cleaning of small hardware components, ensuring they are free from defects and ready for further finishing processes.

Types of Airless Tumblast Shot Blasting Machines We Offer:

- Standard Tumblast Machines: Ideal for small to medium-sized components, these machines provide reliable performance for batch cleaning and surface preparation.

- Continuous Tumblast Machines: Designed for high-volume production, continuous tumblast machines allow uninterrupted blasting with a continuous flow of components, reducing cycle times and increasing throughput.

- Custom Models: AeroWheel Surface Finishing can design and manufacture customized tumblast machines based on the specific needs of your operation, including load capacity, blast media types, and control systems.

Why Choose AeroWheel’s Airless Tumblast Type Shot Blasting Machines?

- Optimized for High Volume: Our machines are designed to handle bulk cleaning operations, making them perfect for industries with high-volume production needs.

- Precision and Efficiency: The airless technology ensures consistent, efficient blasting while reducing energy consumption and abrasive media usage.

- Durable and Cost-Effective: Built to withstand heavy-duty use, our machines require minimal maintenance, making them a cost-effective solution for your industrial cleaning needs.

- Customizable to Your Needs: We offer flexible configurations and tailored solutions to match the specific requirements of your manufacturing process.

- Expert Support: With years of expertise, we provide comprehensive support, from machine selection and installation to ongoing maintenance and after-sales service.

Airless Tumblast Type Shot Blasting Machine Price in Bengaluru:

At AeroWheel Surface Finishing, we offer competitive pricing for our Airless Tumblast Shot Blasting Machines. The final price depends on the capacity, features, and customization options you require. We ensure that you receive the best value for your investment with high-quality, efficient machines tailored to your needs.

For the best Airless Tumblast Type Shot Blasting Machines in Bengaluru, trust AeroWheel Surface Finishing to provide reliable, efficient, and cost-effective solutions for your industrial cleaning needs. Contact us today for more information and to get a customized quote!

Sand Blasting Hopper at AeroWheel Surface Finishing: Efficiency and Precision in Surface Preparation

The Role of Shot Blasting Machine Manufacturers in Industry Growth

Reviews

There are no reviews yet.