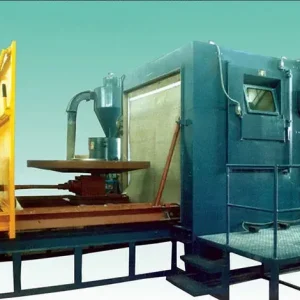

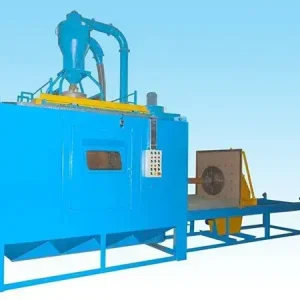

At AeroWheel Surface Finishing, we specialize in the manufacturing of Rotary Indexing Machines tailored to meet the high-speed, high-precision automation needs of industries such as automotive, electronics, manufacturing, and more. Our rotary indexing machines ensure streamlined production, allowing for efficient material handling, assembly, and processing in a wide range of applications.

What is a Rotary Indexing Machine?

A Rotary Indexing Machine is a versatile, automated device that indexes parts or materials into specific positions for machining, assembly, or inspection. The rotary table moves the components into different stations where multiple tasks are performed, improving workflow efficiency and reducing manual intervention. These machines are ideal for operations requiring high-speed accuracy and repeatable performance.

Key Features of AeroWheel Rotary Indexing Machines:

- High-Precision Indexing: Our machines are equipped with servo motors and precision indexing tables, ensuring accurate positioning of components with minimal errors.

- Modular Design: Designed to be scalable and flexible, our rotary indexing machines can be customized to meet the specific needs of your production line.

- Multi-Station Configuration: Allows for the integration of multiple processes such as drilling, tapping, assembling, and quality inspection, all in one machine.

- Automation and Control: Equipped with PLC-based control systems and user-friendly interfaces, our machines offer seamless automation, ensuring minimal downtime and operator efficiency.

- Robust Construction: Built with high-quality materials, our machines are designed for long-term durability, capable of withstanding the rigors of high-volume production.

- Energy Efficient: Engineered for low power consumption, reducing overall operating costs while maintaining peak performance.

Applications of Rotary Indexing Machines:

- Automotive Industry: Ideal for assembly and inspection of automotive components such as gears, shafts, and bearings.

- Electronics Industry: Used for PCB assembly, component insertion, and testing of electronic devices.

- Manufacturing Industry: Involved in the machining, inspection, and assembly of parts like valves, pumps, and fittings.

- Medical Devices: Ensures precise and efficient assembly of medical components, such as syringes, implants, and testing devices.

- Packaging Industry: Rotary indexing machines are widely used for automated filling, capping, and labeling operations in packaging processes.

Types of Rotary Indexing Machines We Offer:

- CNC Rotary Indexing Machines: Integrated with CNC control for precise machining and assembly tasks, ensuring repeatable accuracy for complex operations.

- Automatic Rotary Indexing Machines: Designed for high-speed production lines, automating repetitive tasks and improving overall workflow efficiency.

- Servo-Controlled Rotary Indexing Machines: Equipped with servo motors for high-speed, smooth, and accurate indexing, suitable for sensitive and complex components.

- Manual Rotary Indexing Machines: For smaller, low-volume tasks that require manual operation but still benefit from indexed positioning.

Advantages of Using AeroWheel Rotary Indexing Machines:

- Increased Productivity: Our machines significantly reduce cycle times, allowing for faster processing and higher output without compromising quality.

- Improved Accuracy: Achieve consistent, repeatable results with high-precision indexing, reducing waste and errors.

- Space-Saving Design: Compact and ergonomically designed, our rotary indexing machines save valuable floor space while offering maximum functionality.

- Cost-Efficient Automation: By automating various processes, these machines help lower labor costs and increase throughput, offering a high return on investment.

- Customizable Solutions: We provide tailored machine designs to meet specific industry requirements, ensuring optimal performance for your applications.

Pricing of Rotary Indexing Machines:

Our rotary indexing machines are competitively priced, depending on the machine type, number of stations, and customization options required. CNC and fully automated models come with advanced features and are priced accordingly, with full-service support included in every purchase.

Industries We Serve:

- Automotive Components Manufacturing

- Electronics and Semiconductor Industries

- Medical Equipment Assembly

- Consumer Goods Manufacturing

- Precision Machining and Tooling Industries

For the best Rotary Indexing Machines in Bengaluru, trust AeroWheel Surface Finishing to deliver high-performance, customizable solutions designed to maximize productivity and minimize operational costs. Contact us today for tailored solutions that fit your industrial requirements!

Reviews

There are no reviews yet.