As a leading Shot Peening Machine Manufacturer in Bengaluru, AeroWheel Surface Finishing delivers advanced solutions for surface treatment and metal enhancement. Our machines are tailored to meet the specific needs of industries like automotive, aviation, and defense, where metal fatigue and stress resistance are critical. We offer customized shot peening machines to improve the durability, strength, and performance of components.

What is Shot Peening?

Shot peening is a cold working process used to enhance the lifespan of metal parts by bombarding the surface with small spherical shots. This process induces compressive stresses on the surface, which in turn increases the fatigue strength and resistance to stress corrosion. Shot peening is essential for critical components in industries where parts are exposed to repeated stress cycles.

Key Features of AeroWheel Shot Peening Machines:

- High Precision: Our shot peening machines deliver consistent peening coverage and ensure uniform surface treatment for enhanced component life.

- Customizable Intensity: Adjustable shot velocity and flow rate for controlled surface treatment, ensuring that every component receives the exact peening intensity required.

- Durability: Built from robust materials, our machines are engineered to withstand continuous operation in demanding industrial environments.

- Automation Options: Fully automated systems for high-volume production, reducing manual intervention and increasing productivity.

- Safety Features: Integrated with advanced safety mechanisms to ensure operator protection and environmental compliance.

Benefits of Using Shot Peening Machines:

- Increased Fatigue Resistance: Shot peening induces compressive stress, improving the fatigue life of metal components.

- Stress Corrosion Resistance: Shot peening reduces the likelihood of crack initiation and propagation in critical components.

- Enhanced Durability: Metal parts treated with shot peening are more resistant to wear, corrosion, and impact damage, extending their operational life.

- Surface Hardening: The process strengthens the surface, making it more resistant to deformation and abrasion.

Applications of Shot Peening:

- Automotive Industry: Shot peening is widely used to enhance the durability of engine parts, gear components, crankshafts, and suspension systems.

- Aerospace Industry: Critical components like turbine blades, landing gear, and wing structures undergo shot peening to improve fatigue resistance and reduce wear.

- Defense and Military: Essential in ensuring the structural integrity of armor, artillery parts, and military vehicles subjected to high stress.

- Metalworking: Used in mold-making, tool manufacturing, and other metal-based industries where surface strengthening is vital.

Types of Shot Peening Machines We Offer:

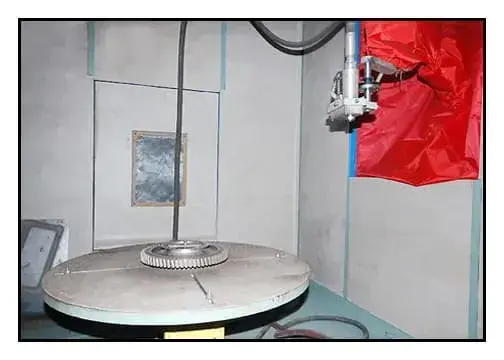

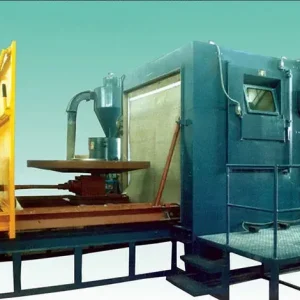

- Automatic Shot Peening Machines: Designed for high-volume production, these machines ensure precise and consistent peening with minimal operator intervention.

- Manual Shot Peening Machines: Suitable for small-scale applications, providing flexibility for low-volume production and custom jobs.

- CNC Controlled Peening Machines: Advanced CNC systems allow for automated, programmable peening, ideal for industries needing customized peening parameters.

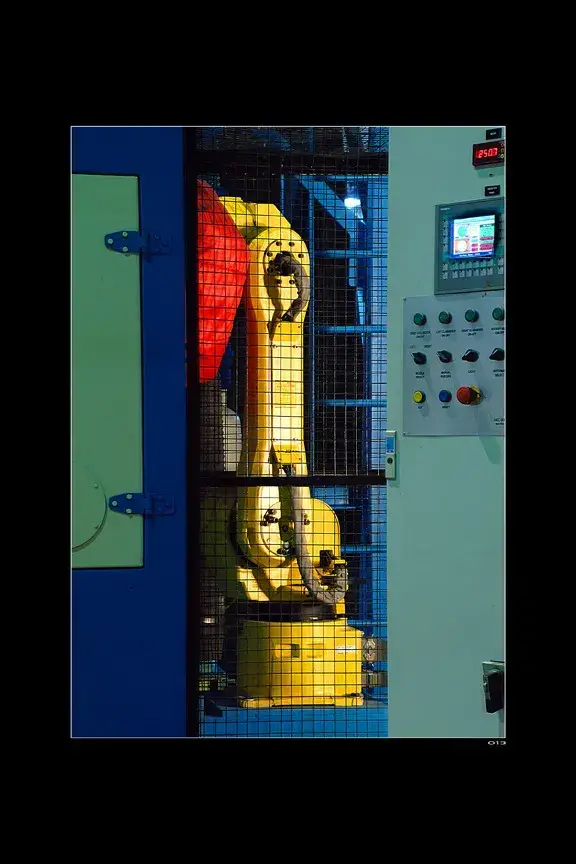

- Robotic Shot Peening Systems: Fully automated with robotic arms, providing precision and repeatability for complex geometries and large components.

Why Choose AeroWheel Surface Finishing?

- Industry Expertise: With years of experience in manufacturing shot peening machines, we understand the specific requirements of diverse industries, ensuring that every machine delivers optimal results.

- Tailored Solutions: We provide custom-designed shot peening machines that meet the exact specifications of your industrial applications.

- Advanced Technology: Our machines are equipped with the latest technology, ensuring precision, reliability, and efficiency.

- Comprehensive Support: From installation to training and after-sales service, we provide end-to-end support, ensuring that your peening systems operate at peak performance.

- Affordable Pricing: We offer competitive pricing on all our shot peening machines, ensuring that you receive the best value for your investment.

Pricing:

Our Shot Peening Machines are available at various price points, depending on the machine’s capacity, automation level, and customization requirements.

For the best Shot Peening Machine Manufacturers in Bengaluru, contact AeroWheel Surface Finishing. Our high-quality machines are designed to improve the strength and longevity of metal components, ensuring maximum performance in every application. Get in touch with us for a custom quote and expert guidance!

Sandblasting Equipment: An In-Depth Guide

Types of Airless Shot Blasting Machines: A Comparative Analysis

Reviews

There are no reviews yet.