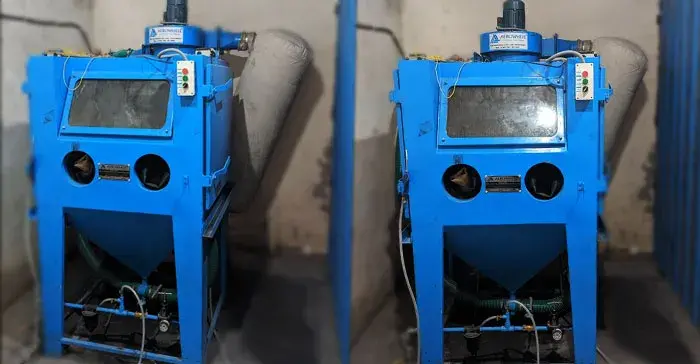

At AeroWheel Surface Finishing, we specialize in designing and manufacturing high-quality Suction/Vacuum Blast Cabinets that cater to the specific needs of various industries. Our suction blast cabinets are built for dust-free operation, providing a clean and efficient workspace while ensuring superior surface treatment for components. Whether you need to remove rust, paint, or contaminants, our vacuum blast cabinets offer a cost-effective, reliable solution for precision blasting.

What is a Suction/Vacuum Blast Cabinet?

A Suction/Vacuum Blast Cabinet is an enclosed system designed for abrasive blasting where compressed air forces abrasive media through a nozzle to clean, smooth, or prepare surfaces. The vacuum system captures dust and debris, maintaining a clean environment and ensuring that the media can be reused efficiently. This system is particularly beneficial for industries that require high precision and minimal dust generation during the blasting process.

Key Features of AeroWheel Suction/Vacuum Blast Cabinets:

- Dust-Free Operation: Our cabinets feature a powerful vacuum system that eliminates dust, ensuring clear visibility for the operator and maintaining a clean workspace.

- Durable Construction: Manufactured from high-grade steel, these cabinets are built to withstand heavy-duty operations, ensuring a long-lasting, robust performance.

- High-Quality Blasting: Achieve uniform surface finishes with our precision nozzles, designed to deliver consistent and accurate abrasive flow.

- Media Recovery System: The vacuum system recovers and recirculates abrasive media, making the operation cost-efficient and reducing media waste.

- Easy Maintenance: Our cabinets are designed for easy cleaning and media replacement, ensuring minimal downtime during operations.

- Operator Safety: Equipped with safety features like protective gloves, clear viewing windows, and effective ventilation systems to protect operators from dust and debris.

Applications of Suction/Vacuum Blast Cabinets:

- Automotive Industry: Ideal for surface cleaning and paint removal from vehicle parts such as engine components, wheels, and frames.

- Aerospace Industry: Suitable for the delicate cleaning of aircraft parts without damaging sensitive components.

- Metalworking Industry: Used for de-scaling, de-burring, and surface preparation of metal parts before coating or painting.

- Restoration Projects: Efficiently removes rust and corrosion from vintage car parts, metal furniture, and other restoration jobs.

- Plastic and Glass Industries: Ideal for deflashing, deburring, and surface preparation of plastic and glass products.

Types of Suction/Vacuum Blast Cabinets We Offer:

- Standard Suction Blast Cabinets: Designed for small to medium-sized components, offering effective surface preparation in a compact, enclosed system.

- Heavy-Duty Vacuum Blast Cabinets: Suitable for larger components and higher volumes, built with robust construction for industrial applications.

- Customizable Blast Cabinets: Tailored to meet your specific blasting requirements, including size, nozzle configuration, and media type.

Why Choose AeroWheel’s Suction/Vacuum Blast Cabinets?

- Superior Blasting Efficiency: Our cabinets are designed to provide consistent, high-quality blasting results, ensuring uniform finishes with minimal effort.

- Cost-Efficient Media Usage: The vacuum recovery system recycles abrasive media, reducing overall operating costs and waste.

- Versatility: Our blast cabinets handle a variety of materials, from aluminum oxide to glass beads and plastic abrasives, providing flexibility across different industries.

- Enhanced Productivity: With a high-speed blasting process and easy-to-operate controls, you can maximize productivity while maintaining precise results.

- Environmentally Friendly: Our suction systems ensure that dust and debris are captured, promoting a cleaner, safer work environment.

Pricing of Suction/Vacuum Blast Cabinets:

Our Suction/Vacuum Blast Cabinets are available at competitive prices, starting from INR 2,50,000 for standard models. For customized or heavy-duty cabinets, prices may vary based on the size, features, and specific customization options. We offer full-service support, including installation and maintenance to ensure long-term performance.

For businesses in Bengaluru and across India, AeroWheel Surface Finishing delivers high-quality Suction/Vacuum Blast Cabinets designed for efficiency, reliability, and cost-effectiveness. Contact us today for a customized solution to meet your abrasive blasting needs!

Best Shot Blasting Machine Manufacturers in India

Understanding the Different Types of Abrasives Used in Shot Blasting

Reviews

There are no reviews yet.