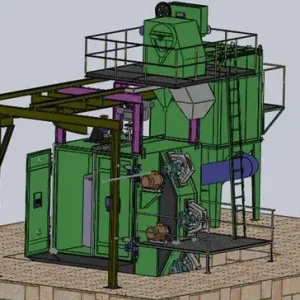

AeroWheel Surface Finishing stands out as one of the most reliable Tunnel Type Shot Blasting Machine Manufacturers in Bengaluru, delivering machines that provide high productivity, efficient surface cleaning, and durable performance. Our tunnel type shot blasting machines are tailored to meet the demands of industries such as automotive, construction, and heavy machinery manufacturing.

What is a Tunnel Type Shot Blasting Machine?

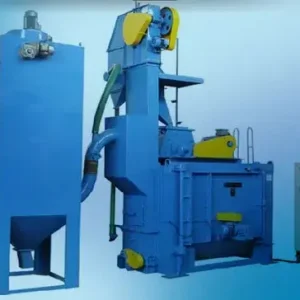

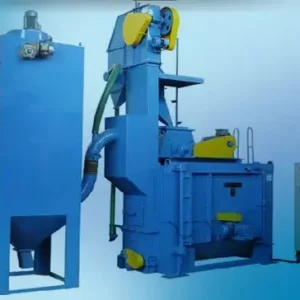

A Tunnel Type Shot Blasting Machine is specifically designed for continuous production lines, where components pass through a tunnel-like enclosure while being blasted with abrasive media. This system is highly efficient for cleaning large batches of workpieces, ensuring a consistent and uniform finish. The tunnel system allows for uninterrupted surface treatment, making it ideal for high-volume production environments.

Key Features of AeroWheel’s Tunnel Type Shot Blasting Machines:

- High Throughput: Our machines are designed for continuous operation, making them perfect for high-speed production lines, with the capability to handle large components and heavy workpieces.

- Uniform Cleaning: The tunnel design ensures that every part of the workpiece is evenly blasted, resulting in a consistent finish.

- Customizable Options: Available in different sizes and configurations, our machines can be tailored to suit specific production capacities and surface treatment needs.

- Durable Construction: Made with heavy-duty materials, our tunnel type shot blasting machines offer long-lasting performance in demanding industrial environments.

- Low Maintenance: With easy-to-access components and automated cleaning systems, our machines require minimal maintenance, reducing downtime and improving overall efficiency.

Applications of Tunnel Type Shot Blasting Machines:

- Automotive Industry: Ideal for cleaning chassis components, engine blocks, and automobile body parts, ensuring that they are free from rust, scale, and other contaminants.

- Construction Industry: Perfect for cleaning structural steel, beams, and metal frames, preparing them for painting or coating.

- Heavy Machinery Manufacturing: Suitable for cleaning large machine components, ensuring that surfaces are properly prepared for assembly or coating.

- Foundries and Forging Plants: Used for cleaning large cast and forged components, removing sand, scale, and oxides, to ensure a high-quality surface.

Types of Tunnel Type Shot Blasting Machines:

- Horizontal Tunnel Type Shot Blasting Machine: Ideal for long workpieces, such as beams, rods, and pipes, this machine is designed for continuous blasting, ensuring a high level of surface cleanliness.

- Vertical Tunnel Type Shot Blasting Machine: Perfect for large vertical structures, such as plates or panels, ensuring even cleaning across the entire surface.

- Customized Tunnel Type Machines: We offer custom solutions to meet specific production requirements, including adjustable conveyor speeds, multiple blast wheels, and advanced filtration systems.

Advantages of AeroWheel’s Tunnel Type Shot Blasting Machines:

- High Efficiency: Our machines are built to handle large volumes of workpieces with precision cleaning, making them ideal for mass production environments.

- Cost-Effective: With minimal maintenance, energy efficiency, and reduced manual labor, our machines offer a high return on investment.

- Customizable Design: We work closely with clients to design machines that fit their specific production processes, ensuring maximum productivity.

- Robust and Reliable: Constructed using high-grade materials, our machines are built to last, ensuring reliable performance over long operational periods.

Why Choose AeroWheel Surface Finishing?

- Industry Expertise: With years of experience in surface finishing solutions, AeroWheel offers cutting-edge technology and expertise in shot blasting machines.

- Custom Solutions: Our team works closely with clients to design machines that meet their specific requirements, ensuring optimal performance.

- Comprehensive Support: We offer installation, maintenance, and after-sales support, ensuring that your machine runs smoothly throughout its lifecycle.

- Competitive Pricing: Our tunnel type shot blasting machines are available at competitive prices, with customization options to meet various budget needs.

For the best Tunnel Type Shot Blasting Machine Manufacturers in Bengaluru, contact AeroWheel Surface Finishing today to explore our high-performance, cost-effective, and customizable solutions for your surface preparation and blasting needs!

Customer Support Services Offered by Shot Blasting Machine Manufacturers

Comparing Prices Among Shot Blasting Machine Manufacturers

Jodhpur's Hanger Heroes: Top Hanger Shot Blasting Machine Manufacturers for Efficient Finishing

Reviews

There are no reviews yet.