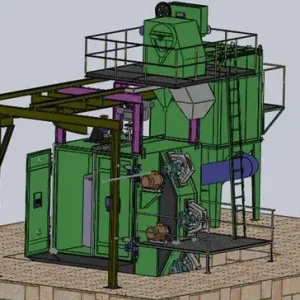

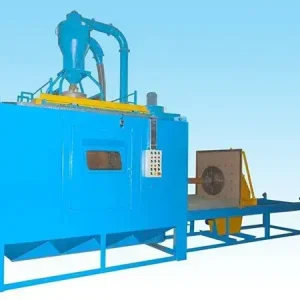

At AeroWheel Surface Finishing, our sand blasting hopper is a vital component in our surface preparation process, delivering consistent and high-quality results across a wide range of applications. Designed to handle both small and large-scale projects, our sand blasting hopper plays a crucial role in ensuring that every surface is meticulously prepared for subsequent treatments or coatings. This article will provide an in-depth look at how our sand blasting hopper works, the technology behind it, and why it’s an essential tool in achieving the perfect finish.

What is a Sand Blasting Hopper?

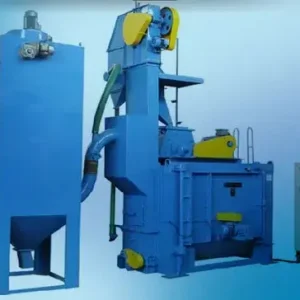

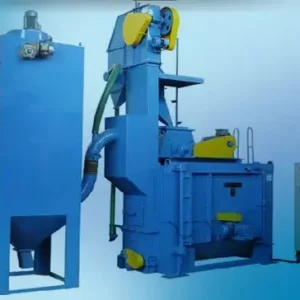

A sand blasting hopper is a specialized device used to store and propel abrasive materials, such as sand, at high velocities to clean or etch surfaces. The hopper serves as a reservoir, holding the abrasive material until it is ready to be used in the blasting process. At AeroWheel, our sand blasting hoppers are engineered to deliver a powerful and precise blast, making them ideal for preparing surfaces by removing rust, paint, scale, and other contaminants.

Advanced Features of AeroWheel’s Sand Blasting Hopper

Our sand blasting hopper is designed with several advanced features that ensure efficiency, safety, and precision in every project we undertake. These features allow us to deliver superior results while maintaining a safe and controlled environment.

1. High-Capacity Design

Our sand blasting hoppers are built to handle large volumes of abrasive material, making them suitable for both small and large-scale projects. The high-capacity design ensures that the hopper can hold enough abrasive to complete extensive blasting operations without the need for frequent refills. This feature is particularly beneficial for industrial applications where time and efficiency are critical.

2. Precision Control Valves

The control valves on our sand blasting hoppers allow for precise regulation of the flow of abrasive material. This level of control is essential for achieving consistent results, as it enables our technicians to adjust the intensity of the blast according to the specific requirements of each project. Whether we’re working on delicate surfaces that require a gentle touch or heavy-duty projects that need more aggressive blasting, our precision control valves ensure the perfect balance.

3. Robust Construction

Durability is key when it comes to equipment used in industrial applications. Our sand blasting hoppers are constructed from high-quality materials that can withstand the rigors of heavy use. The robust construction ensures that the hopper remains reliable and efficient, even under the most demanding conditions.

4. Easy Maintenance and Cleaning

Maintaining the sand blasting hopper is straightforward, thanks to its user-friendly design. Regular maintenance is essential to ensure that the hopper continues to operate at peak performance. Our design allows for easy access to all critical components, making cleaning and maintenance tasks simple and efficient.

The Sand Blasting Process: Achieving the Perfect Surface

The sand blasting process at AeroWheel is a carefully controlled operation that requires precision and expertise. Our team of skilled technicians follows a systematic approach to ensure that each surface is prepared to the highest standards.

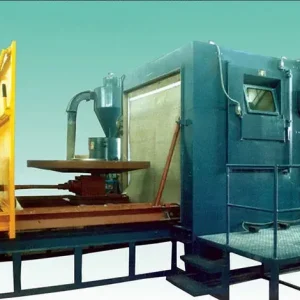

1. Surface Assessment and Preparation

Before the sand blasting process begins, the surface to be treated is thoroughly assessed. This initial assessment allows our technicians to determine the appropriate abrasive material and blasting intensity needed for the project. Surface preparation may involve masking areas that should not be blasted and securing the component within the blasting area.

Innovations by Leading Shot Blasting Machine Manufacturers

Safety Precautions When Operating Shot Blasting Machines

Unveiling Jodhpur's Gems: A Guide to Safe and Reliable Shot Blasting Machine Manufacturers

2. Loading the Sand Blasting Hopper

Once the surface has been prepared, the abrasive material is loaded into the sand blasting hopper. The type of abrasive used depends on the material of the component and the desired finish. Common abrasives include silica sand, aluminum oxide, and garnet. Each material has its own properties that make it suitable for specific applications, from removing rust and scale to creating a smooth, polished finish.

3. Controlled Blasting

The controlled blasting process begins with the precise regulation of the abrasive flow from the hopper. Our technicians adjust the flow rate and pressure to ensure that the abrasive material is propelled at the optimal velocity for the task at hand. The abrasive is then directed onto the surface, where it effectively removes contaminants, old coatings, and imperfections.

4. Post-Blasting Inspection and Quality Control

After the blasting process is complete, the surface is carefully inspected to ensure that it meets the required specifications. Our quality control team checks for uniformity, surface profile, and the complete removal of unwanted materials. If necessary, additional blasting or other surface treatments may be applied to achieve the desired finish.

Why AeroWheel’s Sand Blasting Hopper Stands Out

AeroWheel’s sand blasting hopper is more than just a piece of equipment; it’s a critical component of our commitment to delivering the highest quality surface finishing services. Here’s why our sand blasting hopper stands out:

- Efficiency and Precision: Our hopper is designed to deliver consistent and precise blasting results, ensuring that every surface is prepared to perfection. This efficiency translates into faster project turnaround times and superior quality finishes.

- Versatility: Our sand blasting hopper can handle a wide range of abrasive materials and project sizes, making it a versatile tool for various industrial applications. Whether we’re working on small, intricate components or large, heavy-duty equipment, our hopper is up to the task.

- Safety and Reliability: Safety is a top priority at AeroWheel, and our sand blasting hopper is equipped with features that enhance safety and reliability. From robust construction to precision controls, every aspect of the hopper is designed with the well-being of our technicians and the quality of our work in mind.

- Expertise and Experience: Our team of skilled technicians has the knowledge and experience to get the most out of our sand blasting hopper. Their expertise ensures that each project is completed to the highest standards, with attention to detail and a focus on achieving the best possible results.

Industries We Serve

AeroWheel’s sand blasting services are utilized across a variety of industries, each with unique surface preparation requirements. Our ability to adapt to different materials and project specifications makes us a trusted partner in the following sectors:

- Aerospace: The aerospace industry demands precision and reliability in every component. Our sand blasting hopper is capable of preparing surfaces to the exacting standards required for aerospace applications.

- Automotive: In the automotive industry, the appearance and durability of components are critical. Our sand blasting process ensures that surfaces are properly prepared for painting, coating, or other treatments that enhance both performance and aesthetics.

- Marine: Marine environments are harsh and corrosive, making surface preparation essential for protecting components from the elements. Our sand blasting services provide the necessary foundation for durable, long-lasting coatings.

- Construction and Heavy Industry: Large-scale industrial equipment and structural components require robust surface preparation to ensure longevity and performance. Our sand blasting hopper is capable of handling these heavy-duty applications with ease.

Conclusion

The sand blasting hopper at AeroWheel Surface Finishing is an essential tool in our pursuit of excellence in surface preparation. By combining advanced technology, skilled technicians, and a commitment to quality, we deliver results that not only meet but exceed industry standards. Whether you’re in aerospace, automotive, marine, or heavy industry, AeroWheel’s sand blasting services are designed to provide the perfect foundation for your surface finishing needs.