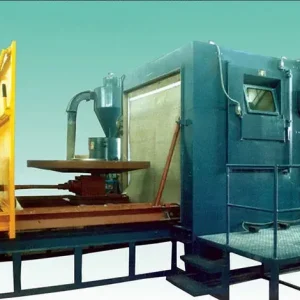

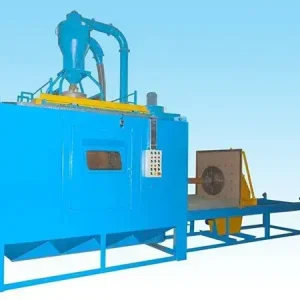

As one of the trusted Sand Blasting Machine Manufacturers in Bengaluru, AeroWheel Surface Finishing provides a comprehensive range of sandblasting machines to suit various industrial needs. Our portable, automatic, and wet blasting machines ensure precision, durability, and efficiency, making them ideal for automotive, construction, metalworking, and other industries requiring surface treatment.

What is a Sand Blasting Machine?

A sandblasting machine is an essential tool for surface cleaning and preparation, used to blast abrasive materials onto surfaces under high pressure. This removes unwanted contaminants such as rust, paint, and scale, leaving the surface ready for coating, painting, or further processing.

Key Features of AeroWheel Sand Blasting Machines:

- High Efficiency: Our machines ensure powerful and consistent performance for fast and thorough surface cleaning.

- Durable Construction: Made from high-grade materials, our machines are designed for long-lasting use in harsh industrial environments.

- Custom Solutions: We provide tailor-made machines suited to the specific needs of your industry, whether it’s portable sandblasting units or fully automated systems.

- Safety Mechanisms: All machines are equipped with advanced safety features, ensuring protection for the operator and the environment.

- Variety of Models: We offer machines in different capacities and configurations, such as manual, automatic, and wet blasting machines.

Types of Sand Blasting Machines We Offer:

- Portable Sand Blasting Machines: Designed for on-site jobs, these lightweight, easy-to-transport machines are perfect for small to medium-sized projects. Equipped with a blasting compressor, these machines are commonly used for cleaning and surface preparation in tight spaces or for mobile operations.

- Automatic Sand Blasting Machines: Ideal for large-scale operations, these machines are fully automated, reducing manual labor and increasing productivity. Perfect for repetitive blasting tasks in industrial settings.

- Wet Sand Blasting Machines: Using a combination of water and abrasive materials, these machines minimize dust and ensure a safer, cleaner blasting environment. They are particularly effective for cleaning delicate surfaces.

- Mini Sand Blasting Machines: These compact machines are perfect for small projects or industries requiring intricate detailing, such as the jewelry or precision engineering sectors.

- Industrial Sand Blasting Machines: Built for heavy-duty applications, these machines are used in industries like shipbuilding, aerospace, and construction where large surface areas need to be prepared for coating or painting.

Applications of Our Sand Blasting Machines:

- Rust and Paint Removal: Efficiently remove rust, old paint, and other contaminants from metal surfaces to prepare them for further coating or painting.

- Surface Cleaning: Used in industries like automotive and construction, our machines provide deep cleaning of metal, concrete, and other materials.

- Surface Roughening: For industries requiring adhesion of coatings or welding, our machines can roughen surfaces to create a better bond.

- Restoration Work: Ideal for restoring antique metalwork, machinery, or industrial parts by removing dirt, rust, and other residues.

- Glass and Stone Etching: Our machines can be used for delicate work like glass bead blasting and stone surface finishing, providing a smooth and polished look.

Why Choose AeroWheel Surface Finishing?

- Expertise: With years of experience, AeroWheel is known for delivering high-performance, reliable sandblasting machines designed to last.

- Tailored Solutions: We offer customized sandblasting machines built to meet your specific industrial requirements, ensuring maximum efficiency and productivity.

- Affordable Pricing: Our machines are available at competitive prices, with options to suit all budgets, from low-cost portable machines to high-end industrial systems.

- Comprehensive Support: We provide installation, training, and after-sales service, ensuring that your sandblasting equipment operates at peak efficiency.

- Eco-Friendly Technology: Our wet blasting machines and other environmentally friendly options ensure that you meet environmental compliance while maintaining effective surface treatment.

Industries We Serve:

- Automotive: For removing paint, rust, and preparing metal parts for further processing.

- Construction: Cleaning and surface preparation of buildings, bridges, and steel structures.

- Metal Fabrication: Surface finishing for welded structures, pipes, and other metal components.

- Aerospace: High-precision surface cleaning and preparation for aerospace components.

- Marine: Surface cleaning and rust removal for ships, boats, and marine equipment.

- Jewelry: Delicate sandblasting techniques used for fine detailing in jewelry making.

Advantages of Using AeroWheel Sand Blasting Machines:

- Improved Surface Quality: Our machines provide smooth, clean surfaces ideal for painting, coating, and finishing.

- Increased Productivity: With our high-performance equipment, tasks are completed faster, improving overall productivity.

- Cost-Effective: Reduce labor and downtime with automated sandblasting systems, ensuring consistent results without increasing operational costs.

- Environmentally Friendly: Our wet blasting solutions minimize dust and airborne particles, making the process safer for the operator and compliant with environmental standards.

Pricing:

The price of sandblasting machines varies based on the type and capacity of the machine. Our pricing for portable sandblasting machines and goes up based on the features and automation level required. We also offer custom-built solutions for industries with specific needs.

For the best Sand Blasting Machine Manufacturers in Bengaluru, trust AeroWheel Surface Finishing for your industrial surface cleaning and preparation needs. Contact us today to get a custom quote tailored to your project requirements.

Advancements in Shot Blasting and Sand Blasting Technology

Reviews

There are no reviews yet.