Shot Blasting Machine

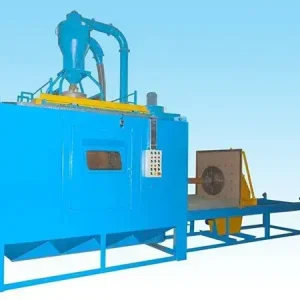

What is a Shot Blasting Machine?

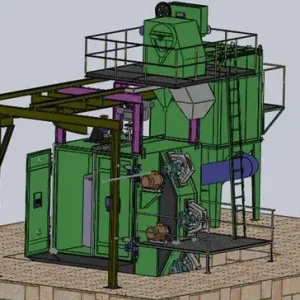

A shot blasting machine is a powerful piece of equipment used in various industries to clean, strengthen, and polish metal surfaces. This machine propels abrasive materials, known as shots, at high velocities onto surfaces to remove contaminants, rust, and old paint, providing a smooth and clean finish.

About the Company

Leading Suppiler & Exporter

ISO Certified

Trustseal Verified

Manufacturer

Transportation Mode

Air Transport

Sea Transport

Land Transport

Payment Terms

RTGS

100% T/T

NEFT

IMPS

UPI

How Does a Shot Blasting Machine Work?

The shot blasting process involves several key components and steps:

- Abrasive Delivery: The machine uses a centrifugal wheel or a compressed air system to propel abrasive materials.

- Blast Chamber: The surface to be treated is placed in a blast chamber where it is exposed to the high-velocity shots.

- Recovery System: After impact, the abrasive material and debris are collected, cleaned, and reused.

- Dust Collection: A dust collection system captures and filters the dust generated during the process.

Types of Shot Blasting Machines

There are various types of shot blasting machines, each designed for specific applications:

1. Tumblast Machines

Tumblast machines are ideal for batch processing of small to medium-sized components. They provide efficient cleaning and finishing.

2. Spinner Hanger Machines

Spinner hanger machines are used for cleaning large and complex parts. They are suitable for components that cannot be tumbled due to their size or shape.

3. Continuous Through Feed Machines

These machines are designed for high-volume production and can process parts continuously. They are commonly used in automotive and manufacturing industries.

4. Table Type Shot Blasting Machines

Table type machines are used for treating flat components like sheets, plates, and fabrications. They provide uniform surface treatment.

5. Portable Shot Blasters

Portable shot blasters are versatile and can be used on-site for maintenance and cleaning applications. They are ideal for small-scale jobs and hard-to-reach areas.

Benefits of Shot Blasting Machines

- Improved Surface Quality: Shot blasting removes impurities, providing a clean and smooth surface ready for painting or coating.

- Increased Durability: The process strengthens metal surfaces, enhancing their resistance to wear and tear.

- Cost-Efficiency: Reduces manual labor and time required for surface preparation.

- Environmental Benefits: Reusable abrasive materials reduce waste and environmental impact.

Applications of Shot Blasting Machines

Shot blasting machines are used in a wide range of industries, including:

- Automotive: Cleaning and preparing automotive parts for coating or assembly.

- Construction: Removing rust and paint from steel structures.

- Aerospace: Ensuring the integrity and cleanliness of aircraft components.

- Foundries: Cleaning castings and forgings.

- Shipbuilding: Preparing ship hulls and other large structures.

How to Choose the Right Shot Blasting Machine

When selecting a shot blasting machine, consider the following factors:

- Type of Material: Determine the type of material and surface you need to treat.

- Production Volume: Assess your production requirements and choose a machine that can handle the volume.

- Space Availability: Ensure you have adequate space for the machine and its operation.

- Budget: Balance between cost and quality to make a cost-effective investment.

- After-Sales Support: Choose a manufacturer that offers reliable customer support and maintenance services.

Maintenance of Shot Blasting Machines

Regular maintenance is essential for the efficient operation of shot blasting machines:

- Inspect and Replace Worn Parts: Regularly check for worn-out parts like blast wheels and nozzles.

- Lubricate Moving Parts: Ensure all moving components are properly lubricated to reduce wear and tear.

- Clean the Machine: Keep the machine clean and free from dust and debris to prevent clogging.

- Monitor Abrasive Quality: Regularly check and replace abrasive materials to ensure consistent performance.

Conclusion

Shot blasting machines play a crucial role in various industries by providing efficient surface preparation and finishing. Choosing the right machine and maintaining it properly can lead to significant improvements in productivity and product quality. Whether you are in the automotive, construction, aerospace, or any other industry, investing in a high-quality shot blasting machine can enhance your manufacturing process.

Shot Blasting Machine Products

Experience precision and durability with Aerowheel’s innovative shot blasting machines. Designed for optimal performance, cleaning, and surface preparation.

- Shot Blasting Machine

- Customized Blasting Cabinets

- Shot Blasting Machine

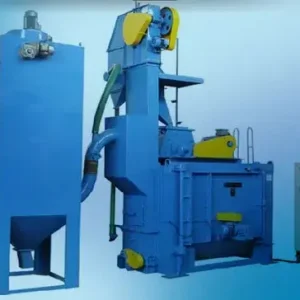

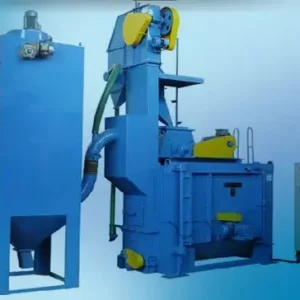

Airless Tumblast Type Shot Blasting Machine Manufacturers in Bengaluru

Rated 0 out of 5 - Shot Blasting Machine

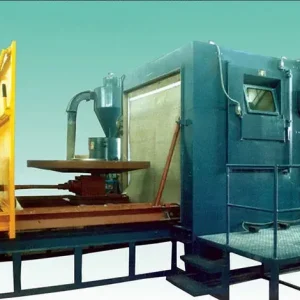

Airless Swing Table Shot Blasting Machine Manufacturers in Bengaluru

Rated 5.00 out of 5

- Customized Blasting Cabinets

Suction/ Vacuum Blast Cabinet Manufacturers in Bengaluru

Rated 0 out of 5 - Customized Blasting Cabinets

Abrasive Blasting Cabinets Price and Manufacturer in Bengaluru

Rated 5.00 out of 5