Tips for choosing Abrasive Blasting Media: At Aerowheel, we often come across clients who are in a dilemma while choosing Abrasive Blasting Media. If you are one of them, please read our blog below and put an end to all your doubts!

What is Abrasive Blasting Media?

Abrasive Blasting is also commonly called Sand Blasting. It is a generic term used for the process of smoothening, shaping, and cleaning a hard surface by forcing solid particles at a high speed against the surface of the object.

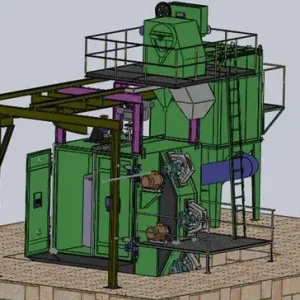

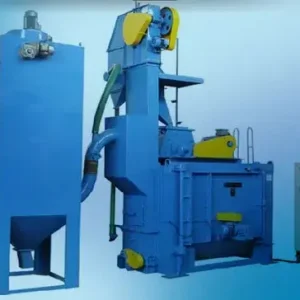

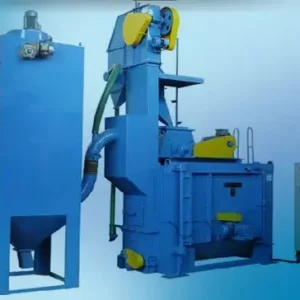

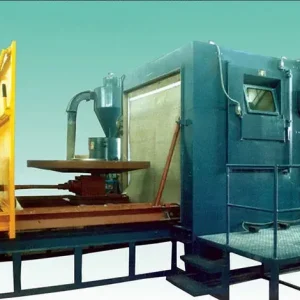

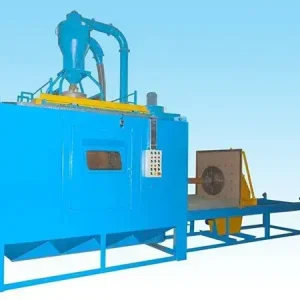

Aerowheel has Abrasive Blasting Cabinets that are used to remove rust, paint stains, and other impairments to objects. Objects that are blasted include Rims, machine parts, parts of cars, and motorcycles.

The process of Abrasive Blasting may also differ in the intensity of propelling the stream of abrasive material. In some cases, it is mild while in others it may be highly abrasive.

Sandblasting equipment typically consists of a chamber in which sand and air are mixed. The mixture travels through a hand-held nozzle to direct the particles toward the surface or workpiece. Nozzles come in a variety of shapes, sizes, and materials. Boron carbide is a popular material for nozzles because it resists abrasive wear well.

Irrespective of other distinguishing features what our Abrasive Blasting Cabinets have in common is that they are universally applicable in their working as well as their blasting materials application achieves the optimum blasting result.

Our Abrasive Blasting Cabinet in an overview

1. Generally applicable for: cleaning, dusting, descaling, hardening, deburring, roughening, compacting, and polishing.

2. Suitable for all kinds of blasting medium.

Overview of Airless Shot Blasting Machines: Working Principles and Applications

Shot Blasting Machine Maintenance and Troubleshooting: Tips from Indian Manufacturers

Benefits of Using Shot Blasting Machines

3. Delivery is completely ready for operation with all necessary connections.

Just as we start the machine, there are some tips that can help us choose the best abrasive medium for our specific blasting usage.

- Blast Media Properties

- Blast Media Description

Blast Media Properties

While you have to choose Abrasive blasting Media, pay attention to the size, shape, density and hardness of the media.

- Size: All things being equal, the bigger the particle, the deeper indentation it will make, but blasting large particles will give you less impacts than than an equal volume of smaller particles. Small particles clean faster, provide better coverage, and result in a more uniform profile.

- Shape: The shape of the article affects how deeply it cuts into the coating and underlying substrate. Shapes are classified according to angularity. Angular particles cut through soft coatings and rust, cleaning faster, and producing sharper anchor patterns. Rounded particles produce a more even, peened surface, good for breaking away hard brittle coatings and mill scale.

- Density: Dense particles impact with more kinetic energy over a smaller surface area, resulting in a deeper profile. Dense particles also deform less, absorbing less energy upon impact.

- Hardness: Generally speaking, the harder the particle, the deeper the profile it will impart, except in cases where a high-velocity hard particle shatters, delivering less than optimum force. Softer abrasives, like organic materials and plastics, are good for removing dirt, oil, grease and paint without creating an anchor pattern in the underlying substrate.

Blast Media Description

- Begin with noble media: It’s always cautious to start with a gentle medium like walnut shells or corn cobs because they won’t cause etching. They are also biodegradable and hence, are the most environmentally-friendly blasting media ever used.

- Glass beads for a shinier metal: To make for a safer yet strong cleaning results, using glass beads onto your automotive parts or stainless steel surface can be a better option.

- Select Aluminum Oxide for Glass Etching: Harder and rough surfaces like ship decks, heavy industrial surfaces needing scraping and repainting alloy for aluminum oxide but moreso, it is finely worked on glass to etch the surface as aluminum oxide is much harder and sharper than glass beads so better know your surface before using it. However, in general cleaning applications too, this media can be applied.

- Plastic Media for Softr Applications: Fiberglass parts are mainly used in the manufacturing of automotive, aerospace and marine products, without etching or stripping and plastic becomes an ideal choice here when you treat your equipment.

- Peening with Steel Media: The steel shot is round in shape and is extensively applied for polishing and peening applications. The plane where it is applied offers a more angular shape and sharper texture. However, it can effectively remove rust, paint or scale from harder steel surfaces.

Read More: What is the difference between Shot Blasting And Sand Blasting Machines?