Types of Shot Blasting Machines

Shot blasting machines are essential in various industries for cleaning, strengthening, and polishing metal surfaces. Different types of shot blasting machines are designed to cater to specific applications and workpieces. Understanding these types helps in selecting the right machine for your needs, ensuring optimal performance and efficiency. Here’s a detailed overview of the main types of shot blasting machines:

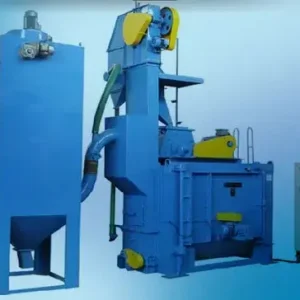

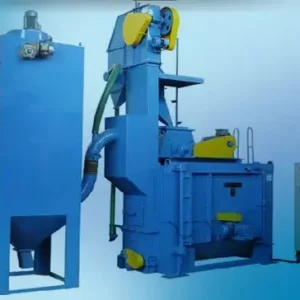

1. Tumble Blast Machines

Description: Tumble blast machines are designed for cleaning and finishing small to medium-sized parts in bulk. They consist of a rotating drum or barrel that tumbles the workpieces while blasting them with abrasive media.

Key Features:

- Rotating Drum: The drum’s rotation ensures even exposure to the blast stream, cleaning all surfaces of the workpieces.

- Bulk Processing: Capable of handling large quantities of small parts simultaneously, making it ideal for mass production.

Applications:

- Cleaning castings and forgings

- Removing rust and scale from small metal parts

- Deburring and deflashing

2. Spinner Hanger Machines

Description: Spinner hanger machines are designed for larger, more complex workpieces. Workpieces are hung on hooks and rotated through the blast stream, ensuring thorough cleaning.

Key Features:

- Rotating Hooks: Workpieces are suspended on rotating hooks or hangers, allowing for comprehensive cleaning.

- Versatile Configuration: Can handle a wide range of part sizes and shapes.

Applications:

- Cleaning and descaling automotive parts

- Preparing surfaces of heavy machinery components

- Removing coatings from larger workpieces

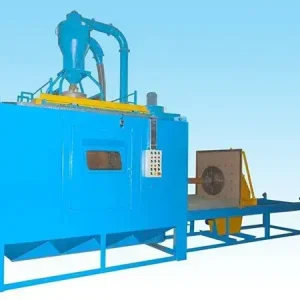

3. Continuous Blast Machines

Description: Continuous blast machines are designed for high-volume production environments. Workpieces are conveyed through the machine on a continuous basis, ensuring efficient and consistent blasting.

Key Features:

- Conveyor System: Workpieces are transported through the blast chamber on a conveyor, allowing for continuous processing.

- High Throughput: Ideal for large-scale production lines, maximizing efficiency and productivity.

Applications:

- Cleaning and finishing parts in automotive and aerospace industries

- Surface preparation for painting and coating

- High-volume cleaning of metal sheets and plates

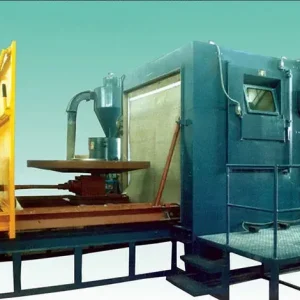

4. Table Blast Machines

Description: Table blast machines are used for larger, flat workpieces. The workpieces are placed on a rotating table within the blast chamber, allowing for thorough cleaning.

Key Features:

- Rotating Table: The table’s rotation ensures all surfaces of the workpiece are exposed to the blast stream.

- Suitable for Large Parts: Can handle large, flat, or irregularly shaped workpieces.

Applications:

Advantages of Airless Shot Blasting Machines over Traditional Blasting Methods

The Impact of Shot Blasting Machines on Corrosion Prevention: Insights from Indian Manufacturers

Exploring the Wide Range of Shot Blasting Machines Offered by Indian Manufacturers

- Cleaning large steel plates and welded structures

- Removing scale and rust from large metal components

- Surface preparation of large parts for coating and painting

5. Overhead Rail Machines

Description: Overhead rail machines are designed for large, heavy, or awkwardly shaped workpieces. Workpieces are suspended from an overhead rail system and moved through the blast chamber.

Key Features:

- Overhead Rail System: Allows for easy handling of large and heavy workpieces.

- Customizable: Can be configured to handle specific workpiece sizes and shapes.

Applications:

- Cleaning and descaling large structural components

- Surface preparation for large industrial equipment

- Removing coatings from heavy machinery parts

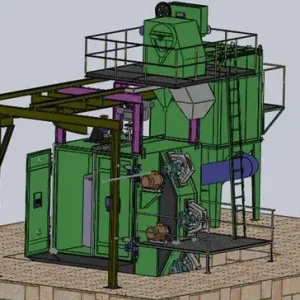

6. Blast Room Systems

Description: Blast room systems are large, enclosed spaces where manual or automated blasting operations are conducted. These systems are used for very large workpieces or high-volume blasting requirements.

Key Features:

- Enclosed Environment: Provides a controlled space for blasting, minimizing dust and debris.

- Flexible Operation: Can accommodate various blasting methods and media types.

Applications:

- Cleaning and preparing large industrial equipment

- Surface finishing of large metal structures and parts

- High-volume blasting operations in shipyards and construction sites

7. Portable Shot Blasters

Description: Portable shot blasters are mobile units designed for on-site blasting operations. They are compact and easy to transport, making them ideal for fieldwork.

Key Features:

- Mobility: Easy to move and set up at different locations.

- Versatility: Suitable for various blasting applications in different environments.

Applications:

- On-site cleaning and preparation of metal surfaces

- Removing rust and paint from outdoor structures

- Surface preparation for repair and maintenance work

Conclusion

Understanding the different types of shot blasting machines and their specific applications helps in selecting the right equipment for your needs. Each type of machine offers unique advantages, from bulk processing of small parts to handling large, complex workpieces. By choosing the appropriate shot blasting machine, you can ensure efficient, high-quality surface preparation and finishing, enhancing your overall production processes and product quality.