The integration of Industry 4.0 technologies has revolutionized various industries, and the shot blasting sector is no exception. Indian manufacturers have embraced Industry 4.0 concepts to transform traditional shot blasting machines into smart, interconnected systems that optimize performance, enhance productivity, and enable predictive maintenance. In this article, we will explore the significant role of Industry 4.0 integration in shot blasting machines, showcasing insights from Indian manufacturers at the forefront of this technological advancement.

- IoT (Internet of Things) Connectivity: Indian manufacturers equip their shot blasting machines with IoT connectivity, enabling seamless communication between machines and a centralized control system. IoT integration allows real-time monitoring of machine performance, operational parameters, and environmental conditions, facilitating data-driven decision-making.

- Remote Monitoring and Control: Industry 4.0 integration enables remote monitoring and control of shot blasting machines. Indian manufacturers offer user-friendly interfaces that allow operators and supervisors to access machine status, adjust parameters, and receive alerts remotely. This feature enhances operational efficiency and flexibility, as experts can remotely address issues and make adjustments without being physically present on the shop floor.

- Predictive Maintenance: By leveraging data collected through sensors and monitoring systems, Indian manufacturers implement predictive maintenance strategies in shot blasting machines. Predictive algorithms analyze data to predict maintenance needs and potential equipment failures, allowing for proactive maintenance and minimizing unscheduled downtime.

- Data Analytics and Process Optimization: Industry 4.0 technologies empower Indian manufacturers to analyze vast amounts of data collected from shot blasting machines. Data analytics helps identify trends, optimize process parameters, and fine-tune machine settings for improved performance and productivity.

- Digital Twin Technology: Digital twin technology is gaining traction in shot blasting machines, especially in advanced systems from Indian manufacturers. A digital twin is a virtual representation of the physical machine, allowing for simulations and performance analysis in a virtual environment. This aids in testing and optimizing new blasting processes without disrupting actual production.

- Artificial Intelligence (AI) Integration: Some Indian manufacturers are exploring the integration of AI algorithms in shot blasting machines. AI can analyze vast datasets, identify patterns, and optimize blasting parameters in real-time, leading to enhanced efficiency, reduced abrasive consumption, and consistent surface quality.

- Automated Process Control: Industry 4.0 integration facilitates automated process control in shot blasting machines. The control system can dynamically adjust blast parameters, media flow, and workpiece positioning based on real-time data, ensuring optimal and repeatable results for each workpiece.

- Advanced Human-Machine Interfaces (HMIs): Indian manufacturers focus on developing user-friendly HMIs that facilitate seamless interaction between operators and shot blasting machines. Advanced HMIs display critical machine data, analytics, and control options, enabling operators to make informed decisions and adjustments easily.

- Integration with Enterprise Resource Planning (ERP) Systems: Indian manufacturers are integrating shot blasting machines with ERP systems to streamline production planning, resource allocation, and inventory management. This seamless integration optimizes production schedules and material usage, leading to increased efficiency and cost savings.

- Digital Connectivity in Smart Factories: Indian manufacturers are leading the way in creating smart factories by digitally connecting shot blasting machines with other equipment and systems within the manufacturing process. Digital connectivity enhances synchronization between different processes, enabling smooth material flow and reducing bottlenecks.

In conclusion, Indian manufacturers are at the forefront of Industry 4.0 integration in shot blasting machines, embracing IoT connectivity, remote monitoring, predictive maintenance, data analytics, digital twin technology, AI integration, automated process control, advanced HMIs, ERP integration, and digital connectivity in smart factories. By embracing these innovative technologies, Indian manufacturers are transforming shot blasting machines into intelligent and interconnected systems, revolutionizing surface preparation processes and setting new standards for efficiency and productivity in the shot blasting industry.

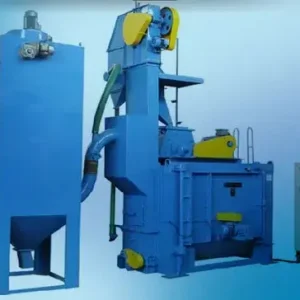

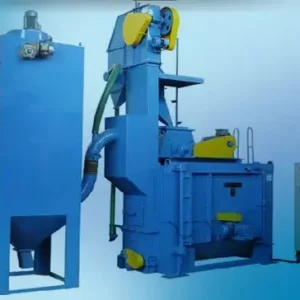

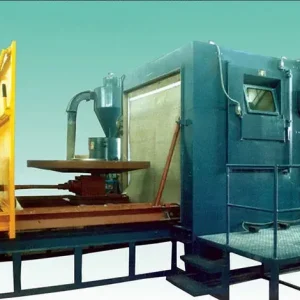

Types of Shot Blasting Machines

How Leading Manufacturers are Reducing the Environmental Impact of Shot Blasting