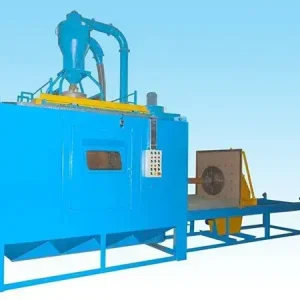

At AeroWheel Surface Finishing, we offer a comprehensive range of Pressure Blast Cabinets designed to meet the demands of industrial cleaning, surface preparation, and finishing. These cabinets are built with advanced features to ensure efficient abrasive blasting, perfect for heavy-duty tasks in industries like automotive, metal fabrication, and manufacturing.

Why Choose Pressure Blast Cabinets?

Pressure Blast Cabinets deliver high-velocity abrasive media at greater pressure compared to traditional suction cabinets, making them ideal for removing tough contaminants like rust, paint, and scale from metal surfaces. They are particularly effective for preparing surfaces for painting, coating, or welding, offering more aggressive and faster results than other blasting methods.

Key Features of Our Pressure Blast Cabinets:

- High Efficiency: Our pressure blast cabinets are equipped with high-performance pressure vessels that ensure a continuous and powerful blast stream, significantly reducing cleaning and finishing time.

- Durable Construction: Built from heavy-duty steel, these cabinets are designed to withstand harsh working environments and extended usage, ensuring longevity and minimal wear.

- Large Workspaces: We provide cabinets in various sizes, offering enough workspace for small to large industrial components.

- Advanced Dust Collection: Each cabinet includes an efficient dust collection system that maintains a clean work environment and ensures operator safety by preventing dust and debris accumulation.

- Easy Operation: The cabinets are designed with ergonomic controls and a simple setup for easy operation, making them ideal for operators of all experience levels.

Applications of Pressure Blast Cabinets:

- Surface Cleaning: Effective removal of rust, paint, and corrosion from metal parts.

- Surface Preparation: Ensures surfaces are ready for coating, painting, or welding, enhancing adhesion and finish quality.

- Deburring and Finishing: Used for deburring, descaling, and finishing of components to achieve smooth surfaces.

- Industrial Component Cleaning: Ideal for cleaning heavy-duty machinery parts and metal fabrications.

Types of Pressure Blast Cabinets We Offer:

- Standard Pressure Blast Cabinets: Designed for general surface preparation tasks, these cabinets provide powerful blasting for medium to large components.

- Customized Pressure Cabinets: Tailored to your specific needs, we offer customized designs for specialized applications, ensuring the best results for your surface preparation processes.

- Automated Pressure Blast Cabinets: For industries requiring high-volume blasting, our automated systems offer consistent performance and minimal operator intervention.

Benefits of AeroWheel’s Pressure Blast Cabinets:

- Faster Cleaning: With higher pressure, our cabinets deliver faster surface cleaning compared to other methods, saving time and increasing productivity.

- Improved Surface Quality: Provides superior surface finishing, ensuring the components are perfectly prepared for further processes like painting or coating.

- Cost-Efficient: Our cabinets are designed for low maintenance and long-lasting performance, reducing operational costs over time.

- Safe and Clean Working Environment: The integrated dust collection system ensures the workplace remains clean, improving operator safety and visibility during blasting operations.

Pricing of Pressure Blast Cabinets:

At AeroWheel Surface Finishing, we offer competitive prices for our high-quality pressure blast cabinets.

Industries We Serve:

- Automotive: Ideal for cleaning and finishing engine parts, frames, and metal components.

- Metal Fabrication: Used for preparing metal surfaces before painting or coating.

- Manufacturing: For heavy-duty industrial cleaning of large machinery and components.

- Aerospace: Provides precision cleaning and finishing for aerospace components.

For high-performance Pressure Blast Cabinets in Bengaluru, choose AeroWheel Surface Finishing. We provide tailor-made solutions for your surface preparation needs, offering quality equipment at competitive prices. Contact us today for more information!

SHOT PEENING PROCESS AND MACHINES

Shot Blasting Machines and Environmental Sustainability: Insights from Indian Manufacturers

Reviews

There are no reviews yet.