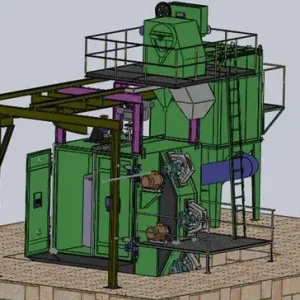

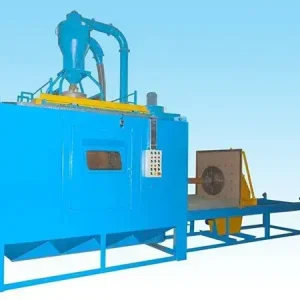

The Spinner Hanger Blasting Machine at AeroWheel Surface Finishing is an advanced piece of equipment designed to deliver unparalleled results in surface preparation and finishing. This machine is an essential tool in our facility, allowing us to handle a wide range of components with precision, efficiency, and consistency. Whether for removing rust, scale, or old coatings, the Spinner Hanger Blasting Machine is a cornerstone of our surface finishing process, ensuring that every component is perfectly prepared for its next phase of treatment.

What is a Spinner Hanger Blasting Machine?

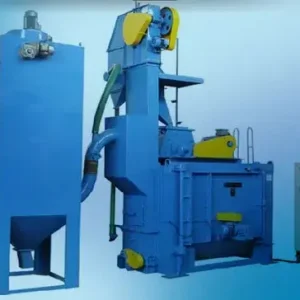

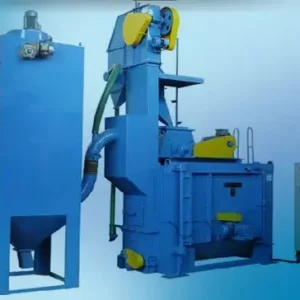

A Spinner Hanger Blasting Machine is a type of shot blasting equipment specifically designed to handle large, heavy, or complex-shaped components. Unlike traditional blasting systems, the spinner hanger machine allows components to be suspended on hooks, which rotate during the blasting process. This rotation ensures that all surfaces of the component are uniformly blasted, even in hard-to-reach areas. At AeroWheel, our Spinner Hanger Blasting Machine is equipped with the latest technology to deliver superior results across various applications.

Key Features of AeroWheel’s Spinner Hanger Blasting Machine

Our Spinner Hanger Blasting Machine is built to provide the highest level of performance, reliability, and versatility. The following features are what make our machine stand out in the industry:

1. Dual Spinner Hangers

Our machine is equipped with dual spinner hangers that allow for simultaneous blasting of multiple components. This feature not only increases efficiency but also ensures that each component is treated evenly and consistently. The dual hangers rotate independently, allowing for comprehensive coverage of every surface.

2. Variable Speed Control

One of the key advantages of our Spinner Hanger Blasting Machine is its variable speed control. This feature allows our technicians to adjust the speed of the hangers and the blasting media, ensuring that the process is tailored to the specific requirements of each component. Whether dealing with delicate surfaces or heavy-duty materials, our machine can be fine-tuned to deliver the optimal finish.

3. High-Efficiency Turbines

The blasting power in our machine is driven by high-efficiency turbines, which propel the abrasive media at high velocities to clean and prepare the surfaces of the components. These turbines are designed for durability and performance, ensuring that the blasting process is both effective and consistent.

4. Comprehensive Dust Collection System

To maintain a clean and safe working environment, our Spinner Hanger Blasting Machine is equipped with a comprehensive dust collection system. This system captures and removes dust and debris generated during the blasting process, preventing contamination and ensuring that the final product is free from impurities.

The Spinner Hanger Blasting Process: A Step-by-Step Overview

The blasting process using our Spinner Hanger Blasting Machine is a meticulously controlled operation that ensures every component is prepared to the highest standards. Here’s how we achieve excellence at every step:

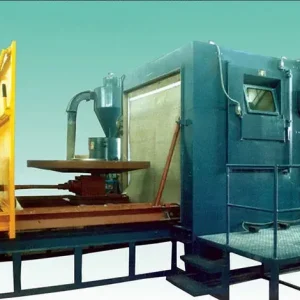

1. Loading the Components

The process begins with carefully loading the components onto the spinner hangers. Each component is securely fastened to ensure it remains stable during the blasting process. The hangers are designed to accommodate a wide range of component sizes and shapes, making the machine versatile and adaptable to different project needs.

2. Selecting the Blasting Media

Choosing the right blasting media is crucial for achieving the desired surface finish. Depending on the material of the component and the required outcome, we select the appropriate abrasive media, such as steel shot, grit, or aluminum oxide. The chosen media is then loaded into the machine, ready for the blasting process.

Conquer Rust and Rejuvenate Metal: AeroWheel - Your Jodhpur Blast Room System Powerhouse

How to Increase the Efficiency of Your Shot Blasting Machine

Emerging Trends in Shot Blasting Machines: Insights from Leading Manufacturers in India

3. Controlled Blasting

With the components securely in place and the media selected, the controlled blasting process begins. The spinner hangers rotate as the abrasive media is propelled at high velocity towards the surface of the components. This simultaneous rotation and blasting action ensure that every part of the component is uniformly treated, even in complex geometries or recessed areas.

4. Monitoring and Adjustments

Throughout the blasting process, our technicians continuously monitor the operation, making adjustments as necessary to ensure optimal results. This includes regulating the speed of the hangers, adjusting the flow of the blasting media, and checking the consistency of the surface treatment. Real-time monitoring allows us to maintain the highest standards of quality and precision.

5. Unloading and Inspection

Once the blasting process is complete, the components are carefully unloaded from the machine. Each component undergoes a thorough inspection to ensure that it meets the required specifications. Our quality control team checks for uniformity, surface profile, and any potential defects. Components that do not meet our stringent standards are reprocessed until they achieve the desired finish.

Advantages of AeroWheel’s Spinner Hanger Blasting Machine

Choosing AeroWheel for your surface finishing needs means benefiting from the numerous advantages offered by our Spinner Hanger Blasting Machine:

- Uniform Surface Treatment: The simultaneous rotation and blasting action ensure that every surface of the component is treated uniformly, resulting in a consistent and high-quality finish.

- Increased Efficiency: The dual hanger design and high-efficiency turbines allow for faster processing times, enabling us to handle large volumes of work without compromising on quality.

- Versatility: Our machine can accommodate a wide range of component sizes and shapes, making it ideal for various industrial applications, from automotive parts to heavy machinery.

- Reduced Downtime: The robust design and reliable performance of our machine mean less downtime for maintenance and repairs, ensuring that projects stay on schedule and within budget.

- Safety and Cleanliness: The integrated dust collection system not only protects the working environment but also ensures that the final product is free from contaminants and impurities.

Industries We Serve

The versatility and precision of our Spinner Hanger Blasting Machine make it a valuable asset across multiple industries. AeroWheel proudly serves clients in the following sectors:

- Automotive: In the automotive industry, surface treatment is critical for both aesthetic and functional purposes. Our machine ensures that components such as wheels, chassis parts, and engine components are prepared to the highest standards.

- Heavy Machinery: The durability and performance of heavy machinery components depend heavily on proper surface preparation. Our Spinner Hanger Blasting Machine delivers the robust treatment needed for these demanding applications.

- Aerospace: Precision is paramount in the aerospace industry, where even the smallest surface imperfection can have significant consequences. Our machine provides the meticulous surface preparation required for aerospace components.

- Construction Equipment: The harsh environments in which construction equipment operates necessitate durable surface treatments. Our machine ensures that these components are properly prepared to withstand the rigors of their working conditions.

Conclusion

The Spinner Hanger Blasting Machine at AeroWheel Surface Finishing represents the pinnacle of efficiency, precision, and reliability in surface treatment. With advanced features, a meticulously controlled process, and a commitment to quality, we deliver surface finishes that exceed industry standards. Whether you’re in automotive, heavy machinery, aerospace, or construction, AeroWheel’s Spinner Hanger Blasting Machine is the ideal solution for your surface preparation needs.