Achieving the best results with shot blasting requires attention to various factors, including proper nozzle selection and pressure settings. Here are some tips to help you achieve optimal results:

- Nozzle Selection: Choose the appropriate blast nozzle based on the material being blasted, the desired surface profile, and the type of abrasive media being used. Nozzles come in different sizes, shapes, and materials. Factors such as nozzle size, orifice diameter, and nozzle angle can impact the blasting pattern, coverage, and efficiency. Consult the manufacturer’s guidelines or seek professional advice to select the right nozzle for your specific application.

- Pressure Settings: Proper pressure settings are crucial for achieving the desired results without damaging the surface. Set the pressure according to the manufacturer’s recommendations and consider the material being blasted. Too high pressure can cause surface deformation or excessive removal, while too low pressure may result in insufficient cleaning or profiling. Find the right balance by adjusting the pressure gradually and monitoring the effects on the surface.

- Distance and Angle: Maintain the appropriate distance between the blast nozzle and the surface being blasted. The distance affects the intensity and coverage of the blast. Start with the manufacturer’s recommended distance and make adjustments based on the desired results and the condition of the surface. Also, pay attention to the angle at which the nozzle is held. An optimal angle helps ensure an even and effective blast pattern.

- Movement Technique: Adopt the right movement technique for consistent and uniform blasting. Overlapping the blast paths is crucial to avoid missed spots and uneven profiles. Maintain a steady and controlled movement, either in straight lines or in a systematic pattern, depending on the size and shape of the surface. Avoid dwelling on any one spot for too long, as it can result in over-blasting or surface damage.

- Abrasive Media Management: Choose the appropriate abrasive media based on the desired surface finish and the material being blasted. Different types of media have varying aggressiveness and profiles. Ensure the media is of high quality and properly graded to achieve the desired results. Regularly monitor the media consumption and replenish as needed to maintain consistent performance.

- Safety Precautions: Prioritize safety when operating shot blasting equipment. Wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, gloves, and protective clothing. Ensure proper ventilation to control dust and fumes. Follow safety guidelines and procedures to prevent accidents and protect both operators and bystanders.

- Regular Equipment Maintenance: Maintain your shot blasting equipment in good working condition. Clean the equipment regularly to prevent abrasive buildup and clogging. Inspect and replace worn-out parts, such as blast nozzles or seals, to ensure optimal performance. Follow the manufacturer’s maintenance schedule and recommendations for lubrication, cleaning, and servicing.

By following these tips and best practices, you can achieve the best results with shot blasting. Remember to consult the equipment manufacturer’s guidelines and seek professional advice when necessary. Continuous learning and experience will help you refine your techniques and achieve consistent and high-quality blasting results.

Go to this : shot blasting machine manufacturers in India

The cost-effectiveness of shot blasting compared to other surface preparation methods.

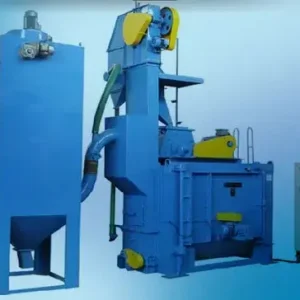

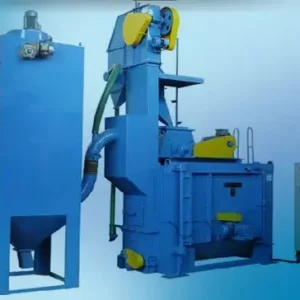

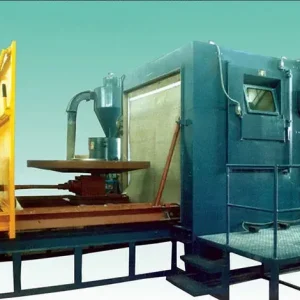

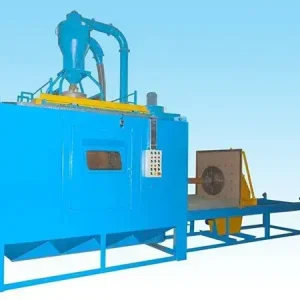

Unveiling the Powerhouse: Airless Swing Table Shot Blasting Machine Manufacturers in Jodhpur

Sand Blasting Hopper at AeroWheel Surface Finishing: Efficiency and Precision in Surface Preparation