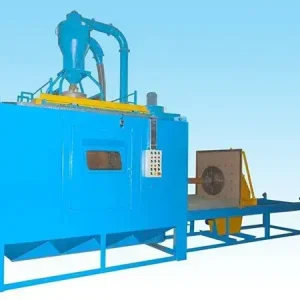

At AeroWheel Surface Finishing, we specialize in the production and supply of abrasive blasting cabinets designed to handle all types of surface cleaning and preparation tasks. Our cabinets are built for durability, precision, and efficiency, making them an essential asset for industries requiring high-quality surface finishing solutions. Whether you’re looking for a manual blasting cabinet or an automated system, we offer the best prices and top-notch equipment tailored to your needs.

Types of Abrasive Blasting Cabinets We Offer:

- Suction Blast Cabinets: Designed for light to medium-duty tasks, these cabinets use a suction mechanism to draw the abrasive media, making them ideal for surface cleaning, rust removal, and paint stripping. They are perfect for small to medium-sized components.

- Pressure Blast Cabinets: Built for heavy-duty applications, pressure blast cabinets deliver abrasive media at higher speeds, making them ideal for tougher surfaces and more intensive cleaning jobs. These are commonly used in industrial applications.

- Wet Blasting Cabinets: These cabinets combine water with abrasive media, reducing dust and providing a more controlled blasting environment. Ideal for industries where dust control is critical.

- Automated Blasting Cabinets: For high-volume production environments, our automated cabinets provide consistent performance with minimal manual intervention. They offer precision blasting for parts that require detailed surface treatment.

Features of Our Abrasive Blasting Cabinets:

- Robust Construction: Our cabinets are built from high-quality steel to withstand the rigors of daily use in industrial environments.

- Efficient Dust Collection System: Each cabinet comes equipped with a dust collection system that keeps the workspace clean and ensures operator safety.

- Multiple Nozzle Options: We offer various blast nozzles to ensure the right level of precision for your specific tasks.

- Easy Maintenance: Designed for easy access, our cabinets allow for quick maintenance and part replacement, ensuring long-lasting performance.

- Customizable Sizes: We offer cabinets in a variety of sizes to accommodate everything from small parts to larger industrial components.

Benefits of Using AeroWheel’s Abrasive Blasting Cabinets:

- Enhanced Surface Preparation: Achieve superior surface finishes with our precise blasting cabinets, ensuring optimal results for painting, coating, or finishing applications.

- Cost-Effective: Our cabinets are designed to be energy-efficient and require minimal maintenance, lowering operational costs.

- Improved Productivity: With faster cycle times and reduced manual labor, our cabinets increase production output for businesses in automotive, aerospace, and metalworking industries.

- Operator Safety: Each cabinet is equipped with ergonomic controls and advanced dust filtration systems to ensure a safe working environment.

Industries We Serve:

- Automotive: Perfect for cleaning engine parts, frames, and body components.

- Metal Fabrication: Ideal for surface preparation, rust removal, and finishing of metal parts.

- Aerospace: Used for precise cleaning of delicate components in aircraft maintenance and manufacturing.

- Manufacturing: Suited for industrial equipment cleaning and surface finishing tasks.

Pricing of Abrasive Blasting Cabinets:

At AeroWheel Surface Finishing, we offer competitive pricing on all types of abrasive blasting cabinets in Bengaluru. Here’s a general price range based on cabinet types:

- Suction Blast Cabinets: Depending on customization and automation features.

- Pressure Blast Cabinets: Depending on customization and automation features.

- Wet Blasting Cabinets: Depending on customization and automation features.

- Automated Blasting Cabinets: Depending on customization and automation features.

Why Choose AeroWheel Surface Finishing?

- Expertise: With years of experience, we provide expert guidance in selecting the right cabinet for your specific needs.

- Customization: We offer tailor-made solutions to meet the unique requirements of your business, from size to blasting intensity.

- Durability: Our cabinets are made from heavy-duty materials, ensuring long-lasting performance even in the most demanding environments.

- Fast Delivery: We ensure quick turnaround times on all orders, with prompt delivery across Bengaluru and India.

Applications of Abrasive Blasting Cabinets:

- Surface Cleaning: Ideal for removing rust, old paint, and corrosion from metal surfaces.

- Surface Preparation: Achieve a perfectly smooth surface, ready for coating, painting, or welding.

- Deburring and Finishing: Used to remove sharp edges and burrs from manufactured parts, providing a smooth finish.

- Paint and Coating Removal: Efficiently strip away old layers of paint or coatings without damaging the underlying material.

Choosing the Right Shot Blasting Machine Manufacturer in India: Factors to Consider

Conquer Surface Imperfections with AeroWheel's Airless Swing Table Shot Blasting Machine

Conquer Rust and Rejuvenate Metal: AeroWheel - Your Jodhpur Blast Room System Powerhouse

Pradeep Saran –

Hey fellow surface enthusiasts! I recently got my hands on an Abrasive Blasting Cabinet for AeroWheel Surface Finishing, and let me tell you, it’s been a game-changer for my projects here in Jodhpur city. This nifty piece of machinery has not only made the job easier but also upped the quality of my surface finishes.

First off, let’s talk about the price. We all know how crucial it is to find a sweet spot between quality and affordability. I did my fair share of research, and I must say, the price of the Abrasive Blasting Cabinet was quite reasonable. I managed to snag a great deal, and considering the efficiency it brings to the table, it’s definitely worth the investment.

Now, onto the manufacturer. I opted for a trusted manufacturer in India, and I couldn’t be happier with my choice. The build quality is top-notch, and it’s evident that they’ve put a lot of thought into designing a product that can withstand the demands of AeroWheel Surface Finishing. The durability alone is enough to convince me that I made the right call.

Living in Jodhpur, where the dust and sand can be a real challenge for surface finishing, this abrasive blasting cabinet has proven to be a reliable ally. The enclosed design ensures that the abrasive material stays where it’s supposed to, making the workspace much cleaner and safer. No more worrying about contaminants ruining my hard work!

One standout feature is the efficient blasting mechanism. The cabinet provides a controlled environment for the blasting process, allowing me to achieve a consistent and precise finish on AeroWheels. The visibility inside the cabinet is excellent, thanks to well-placed lighting, making it easy to monitor the progress of the blasting.

Cleanup is a breeze too. The cabinet comes equipped with a dust collector that efficiently sucks up the debris, keeping the workshop tidy. This not only saves time but also makes the entire process more eco-friendly by minimizing waste.

All in all, I’m thoroughly impressed with the Abrasive Blasting Cabinet for AeroWheel Surface Finishing. It’s a reliable, efficient, and reasonably priced solution that has elevated the quality of my work here in Jodhpur. If you’re serious about achieving top-notch surface finishes, this is definitely a tool worth considering. Happy blasting, fellow craftsmen!